Vacuum Helium Leak Test Service

Any Leak. Any Size. Anywhere. We Find It.

Vacuum leaks can lead to inefficiencies and costly downtime. The Inficon UL-1000 is an essential tool designed to optimize your company’s operations. Our leak detection equipment and 40+ years of experience allow us to quickly pinpoint any leak in your high vacuum system.

Finding Leaks With Efficiency

High Accuracy

Helium leak testing offers exceptional sensitivity, even for systems with low leak-up rates.

Reliability

Better repeatability, shorter cycle times, and less susceptibility to external environmental factors.

Cost Savings

Identifying and fixing potential issues early helps avoid costly repairs and replacements in the future.

Leak Test Scope of Work

How It Works

The leak detector is connected to the pump inlet port and calibration is verified using the internal helium leak standard within the leak detector. A specialized wand is used with a micrometer needle valve to introduce helium into suspected leak areas.

Pinpointing the leak source is a lost art. It takes patience and several separate sweeps starting with broad strokes to highlight regions of vacuum loss leading to ever more minute introductions of helium at decreasing intervals, to allow helium to be swept through the system.

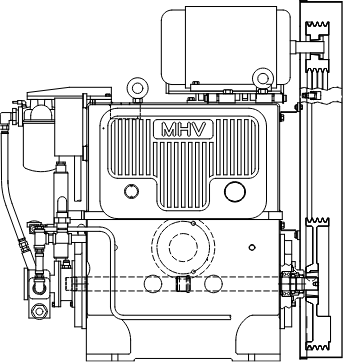

The process is time consuming, but at MHV we have found every source of vacuum loss every time, 100% success guaranteed. Even leaks that have kept furnace chambers from being in operation for several years, we found them in 30 minutes, and fixed them in another 30. A call to us first, as soon as a problem becomes apparent, could save millions in lost production.

Verification & System Guarantee – After repairs, the system is retested to confirm 100% leak-free performance.

Quick-Care Service Area

MHV’s Quick-Care service network ensures fast response times for preventative maintenance and emergency repairs. If you’re in within our 410 mile service area, we can be there when you need us. Outside of that area? We can still offer service, but travel time and expense increases.

Michigan (Full Coverage)

Wisconsin (Full Coverage)

Ohio (Full Coverage)

Indiana (Full Coverage)

Illinois (Partial Coverage)

Iowa (Partial Coverage)

Helium Leak Testing FAQs

Helium leak detection is one of the most precise methods available for identifying leaks in industrial vacuum systems. It can detect leaks as small as 1 x 10⁻¹² mbar·L/s, making it highly effective for ensuring system integrity. Accuracy is a measure of finding a leak, and helium’s small molecular size and inert properties allow it to reveal even the most microscopic pathways that other methods may miss. This level of accuracy is critical for high-vacuum applications where even minor leaks can compromise performance.

This depends on the complexity and size of the system being checked. For example, we leak-checked a VAR furnace that had been out of production for two years and found the leak in just ten minutes. A CVA operating across seven floors with multiple vacuum pumps and blowers can take about an hour to fully check.

Yes—we can perform on-site testing. Your vacuum system will need to be shut down for a proper helium leak check to be conducted. Testing on-site ensures we evaluate the pump under real-world conditions and identify any system-specific issues affecting performance.

Because we have hands-on experience operating heat-treating furnaces and smelting systems, we know exactly where leaks are likely to form. And thanks to our extensive leak-checking across a wide range of applications, we’ve found leaks in places others assume are leak-proof. Between the two, no leak escapes us. But finding the leak is only part of what we do—we also diagnose the cause, engineer solutions, and machine the components needed to seal it for good. MHV is a true one-stop solution—built to keep your operations running.