Why Rebuild?

Remanufacturing delivers the same high performance at a fraction of the cost, all while extending your pump’s lifespan. Failure happens in harsh industrial service. MHV remans match your pump’s core: we measure clearances, machine parts in-house, and ensure proper mating for beyond OEM performance, again and again, for the pump’s life.

60%

Savings compared to buying new

2X

Faster turnaround time than waiting on a new OEM pump

100%+

Peak performance restored to meet or exceed OEM specs

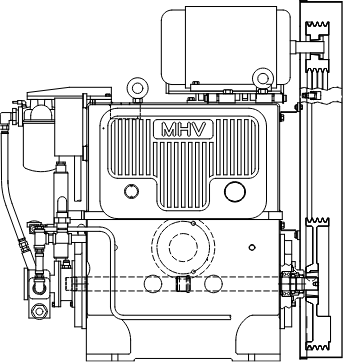

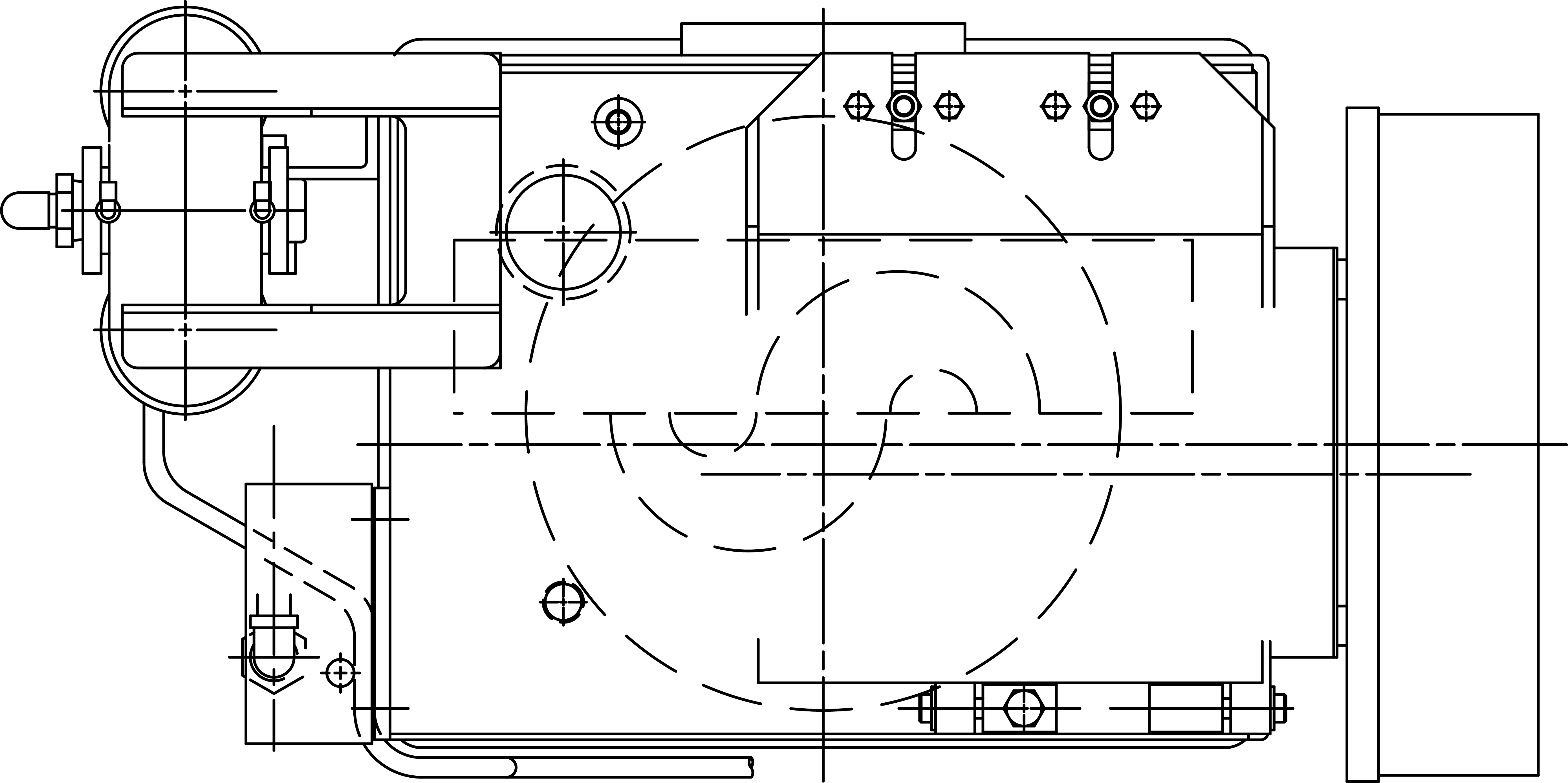

Uptime+ Vacuum Pump Repair & Rebuild

Save Money. Cut Downtime. Clinch Efficiency.

Uptime+ Process

Worn-out vacuum pumps are no match for our remanufacturing process. We inspect every component, run it through our checklist, and turn your pump to OEM or better standards, no shortcuts.

Select Step to Learn More

Step 1 – Evaulate

Step 2 – Clean

Step 3 – Machine

Step 4 – Assemble

Step 5 – Test

Step 6 – Finish

Step 7 – Warranty

Evaulate

We inspect and measure every component to determine how to get your pump back to OEM specs.

What to Expect From Uptime+

Dynamic Balancing

Every Stokes 412 pump is balanced to minimize vibration that can damage your piping and infrastructure.

Dynamic Testing

We subject every pump to rigorous functional testing to ensure your remanufactured pump works as it should.

Fully Inspected

We perform an extensive disassembly, measuring and testing every part to uncover what’s wrong and fix issues that may arise later.

OEM Tolerances

We bring every part back to OEM specs and tolerances, meaning your remanufactured pump is as good as, if not better than, new.

Pump Improvements

We don’t stop at OEM design. We compile our 40+ years of experience in the industry to improve your pump, extending its life even beyond new.

Inspection Manuals

We’ve built and follow extensive manuals when inspecting your pump – a combination of OEM manuals, improvements, and our years of expertise in building and remanufacturing vacuum pumps.

Sentinel System - Ultimate Pump Monitoring

When Downtime Isn’t an Option, They Choose MHV.

"MHV found a blower… that met all our operating parameters… They designed and machined an adapter and had the entire package to us in a week."

Engineer

Coatings Corporation

"We were able to reduce our spare pumps due to shorter lead times, and we cut inventory costs by $43K.”

Maintenance Manager

Global Heat Treater

When Downtime Isn’t an Option, They Choose MHV.

“Great service and value provided. Since having an HS-35 Diffusion pump reworked by MHV, we’ve experienced considerably better operation…”

Plant & Facilities Manager

Domes & Mirrors Manufacturer

“When [MHV] came in to survey our facility, I learned more about vacuum systems in 2 hours than I had in 5 years."

Plant Engineer

Global Aerospace Manufacturer

When Downtime Isn’t an Option, They Choose MHV.

“...all services [are] turnkey, whether engineering or machining – it is all performed by MHV. Nothing is subcontracted out.”

Maintenance Manager

Global Heat Treater

“Great service and value provided. Since having an HS-35 Diffusion pump reworked by MHV, we’ve experienced considerably better operation of the unit in our application. I would highly recommend using them.”

Plant & Facilities Manager

Domes & Mirrors Manufacturer

Brands for Remanufacturing

We specialize in remanufacturing vacuum pumps from a wide range of high-quality brands. We’re one of the original Stokes authorized remanufacturers – a title we’ve held since 1985.

Remanufacturing FAQs

Remanufacturing is all we do—never just a repair. Every component is machined to OEM tolerances using original fixturing methods—no shims, no adhesives, no shortcuts. That means your equipment can be remanufactured again and again. Oil-sealed high-vacuum systems are designed to break and be rebuilt—but an MHV remanufacture extends the time between cycles, keeping your equipment running longer and more reliably.

Uptime+ remanufactures take about as long as a standard reman. We apply the same strict quality standards to every build, with upgraded parts included. If in-line filtration is added, lead time may extend by a few days. Thanks to our in-house inventory of American-cast hard parts, delays are minimal.

Yes—a one-year warranty, or 18 months after delivery if the equipment isn’t installed right away—and it’s a warranty we stand behind.

Absolutely—the Sentinel System, along with any additional labor and parts, will be included in your quote and installed on the final pump assembly before it's crated and shipped back to you.