Optimize Your Vacuum Pump System

Increase Performance, Reduce Costs

An underperforming vacuum system leads to higher energy costs, reduced efficiency, and unnecessary downtime. Our optimization service ensures your system is operating at its best.

Why Optimize?

Extended Life

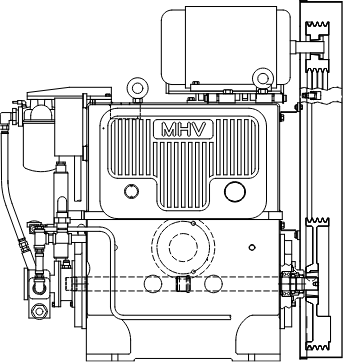

Built from American class 40 grey iron with 4150 heat treated steel internals, our units resist wear, hold clearances, and maintain proper vacuum. Precision machining locates the shaft overbore center to protect the core casting and extend service life.

Dedicated Support

MHV puts industry-leading service at your fingertips. We guide furnace operation, target vacuum levels, and equipment selection with unmatched remanufacturing expertise.

Identify Inefficiencies

As vacuum pump technologies continue to advance and process furnaces adapt to such changes MHV is uniquely positioned to adapt, apply, and administer case specific solutions.

Free System Analysis

Worn-out vacuum pumps are no match for our remanufacturing process. We inspect every component, run it through our checklist, and return your pump to OEM or better standards, no shortcuts.

Select Step to Learn More

Step 1 – System Inspection

Step 2 – Efficiency Analysis

Step 3 – Custom Optimization Plan

Step 4 – Implementation

System Inspection

Our industry leading system inspection includes a full runthrough of every piece of critical vacuum pump/blower equipment required for proper vacuum system operation, including (rotary lobe blower, rotary piston pump, rotary vane pump, diffusion pump, liquid ring pump, turbo chiller, and oil filtration). Our holistic inspection service is a result of 40 plus years not only servicing high vacuum equipment, but engineering and operating the systems requiring said equipment.

When Downtime Isn’t an Option, They Choose MHV.

"MHV found a blower… that met all our operating parameters… They designed and machined an adapter and had the entire package to us in a week."

Engineer

Coatings Corporation

"We were able to reduce our spare pumps due to shorter lead times, and we cut inventory costs by $43K.”

Maintenance Manager

Global Heat Treater

When Downtime Isn’t an Option, They Choose MHV.

“Great service and value provided. Since having an HS-35 Diffusion pump reworked by MHV, we’ve experienced considerably better operation…”

Plant & Facilities Manager

Domes & Mirrors Manufacturer

“When [MHV] came in to survey our facility, I learned more about vacuum systems in 2 hours than I had in 5 years."

Plant Engineer

Global Aerospace Manufacturer

When Downtime Isn’t an Option, They Choose MHV.

“...all services [are] turnkey, whether engineering or machining – it is all performed by MHV. Nothing is subcontracted out.”

Maintenance Manager

Global Heat Treater

“Great service and value provided. Since having an HS-35 Diffusion pump reworked by MHV, we’ve experienced considerably better operation of the unit in our application. I would highly recommend using them.”

Plant & Facilities Manager

Domes & Mirrors Manufacturer

Common Optimization Questions

Here are some common optimization methods: Quality leak checks and proper leak mitigation result in faster pump-down times and more efficient process performance. Upgrading to high-efficiency motors on all critical high-vacuum equipment is a no-brainer. Well-balanced rotary piston pumps also help reduce inertial energy loss.

The call is free—including video chat and system document review—driven by our professional curiosity and commitment to quality. It’s why we remain industry leaders.

Stokes including 212, 412 - rotary piston pumps, Stokes 310 blower, Roots 615, 622 - rotary lobe blowers.

Yes—and it’s the most desirable outcome for both MHV and our clients. While on-site evaluations aren’t free, the value they bring is often evident within the first quarter after implementing optimization solutions.