Maximize Uptime with Active Pump Monitoring

Smarter Monitoring,

Fewer Breakdowns

Sentinel’s sensor package with PLC control monitors oil pressure, filtration efficiency, performance consistency and more. Real-time diagnostics and remote monitoring deliver instant insights into critical pump parameters, allowing your team to detect issues early and take action before a breakdown occurs.

Key Benefits

Proactive maintenance alerts to prevent failures

Reduced downtime and extended pump life

Remote monitoring and real-time diagnostics

Seamless integration with existing vacuum pump systems

Sentinel Stands Guard

System Features

Lube Pressure Sensor — Detects oil pressure drops before they cause damage

Delta P Sensor – Measures pressure differential for filtration efficiency

Hour Meter – Tracks operating time for maintenance scheduling

Flywheel Proximity Sensor – Monitors rotational speed for performance consistency

Oil Level Sensor – Ensures proper lubrication levels at all times

Onboard PLC with Internet Protocol – Enables remote access and monitoring

Pilot Lamps – Alerts for low oil, high temperature, or belt issues

Oil Temperature Sensor – Prevents overheating by tracking oil temperature fluctuations

Proven Protection for Your Bottom Line

Preventative maintenance yields cost efficiency. Driven by in-house machining, Sentinel’s high precision and accurate tolerance ensure the real-time insights you need.

65%

Reduction in downtime

85%

Increase in Pump Lifespan

100%

Fewer Service Calls

When Downtime Isn’t an Option, They Choose MHV.

"MHV found a blower… that met all our operating parameters… They designed and machined an adapter and had the entire package to us in a week."

Engineer

Coatings Corporation

"We were able to reduce our spare pumps due to shorter lead times, and we cut inventory costs by $43K.”

Maintenance Manager

Global Heat Treater

When Downtime Isn’t an Option, They Choose MHV.

“Great service and value provided. Since having an HS-35 Diffusion pump reworked by MHV, we’ve experienced considerably better operation…”

Plant & Facilities Manager

Domes & Mirrors Manufacturer

“When [MHV] came in to survey our facility, I learned more about vacuum systems in 2 hours than I had in 5 years."

Plant Engineer

Global Aerospace Manufacturer

When Downtime Isn’t an Option, They Choose MHV.

“...all services [are] turnkey, whether engineering or machining – it is all performed by MHV. Nothing is subcontracted out.”

Maintenance Manager

Global Heat Treater

“Great service and value provided. Since having an HS-35 Diffusion pump reworked by MHV, we’ve experienced considerably better operation of the unit in our application. I would highly recommend using them.”

Plant & Facilities Manager

Domes & Mirrors Manufacturer

Sentinel System FAQs

Have questions about the Sentinel System? As the only vacuum pump manufacturer and remanufacturer to develop an onboard monitoring system, MHV ensures seamless integration and proactive maintenance to keep your pumps running longer.

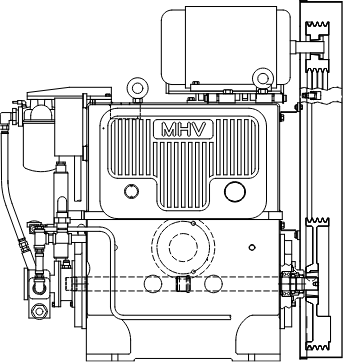

Installation is part of final assembly on an HD300 or HS430 Pump. Installation can also be purchased as an upgrade on 412H11 and 412J14 Stokes pumps (one of several MHV Uptime+ Upgrades available).

This system can digitally communicate through Ethernet connection with any client’s existing plant operation monitoring system.

Operating software is loaded into the PLC. No other software is required.

The Sentinel system is included on our MHV HD300 or HS430 Pumps. It can also be purchased as an MHV Uptime+ upgrade for any Stokes 412 remanufacture.

The oil reservoir is reworked to accommodate a multiple level liquid sensor. An oil pressure sensor is piped into the main oil supply line. A proximity sensor is mounted behind the pump flywheel that senses a puck attached to the flywheel.