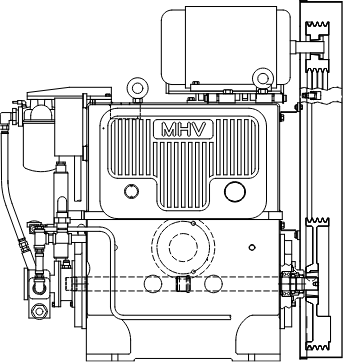

MHV Industrial Vacuum Pumps

Designed for Durability, Built for Performance

We design vacuum pumps to withstand the harshest conditions and deliver consistent, reliable performance. Each model is engineered with precision and built using high-quality components to ensure longevity and efficiency. Explore our three models–SD 300, HD 300, and HS 430–and find the perfect pump to meet your industrial needs.

HD300

The HD 300 introduces full-pressure lubrication to all internal parts, driven by the pump’s mainshaft. It features particulate and acid filtration spin-on oil filters with half-micron ratings. Standard failsafe lubrication ensures oil flow under failure conditions. An hour meter and delta P pressure readout monitor filter performance.

HS430

The HS 430 increases pump RPM to deliver 400 CFM at the inlet. Its lubrication system matches the HD 300, with up to half-micron filtration and drilled hinge bars for critical oil delivery. It runs on a 20-HP Baldor “XE” TEFC motor with an optional VFD for energy efficiency. With routine filter media changes MHV's HS430 surpasses all industry standards, being capable of 24/7 operational service times exceeding 60,000 hours.

The MHV Difference

Bolt-In Replacement

With a size and shape like your existing Stokes 412 pump, our vacuum pumps can be easily bolted into your space.

On-Board Filtration

Our pumps automatically flush out particulates and free acid radicals for reduced wear rates and more runtime between rebuilds.

Failsafe Lubrication

In the event of the attached oil pump’s failure, atmospheric pressure pushes oil into the vacuum pump.

U.S. Manufactured Parts

Our castings are manufactured here in America, and that commitment to American-made parts ensures long-lasting quality.

Sentinel System Add-On

Sensors, gauges, and an onboard PLC alert you of maintenance needs to extend pump life. For HD300, HS430, Stokes 412H11, 412J14.

Drilled Hinge Bars

Delivers oil directly to the wear zone between hinge bar and piston slides—flushing out debris where buildup typically occurs to avoid vacuum loss pressure.

Pumps & Blowers From More Leading Brands

You’ve heard about our standards. If it’s not MHV, you can bet we only offer pumps and blowers from brands known for their reliability and performance. For all brands under our roof, you can count on the MHV commitment to expert maintenance, parts and remanufacturing. Explore each brand to learn about associated services and solutions.